HIGH PERFORMANCE CUTTER FROM ZÜND

Every day more than 17.000 customers worldwide trust in Zünd's digital cutting systems. Among them are the best-known companies in the packaging industry, who have one thing in common:

The desire for economical, flexible and compatible solutions.

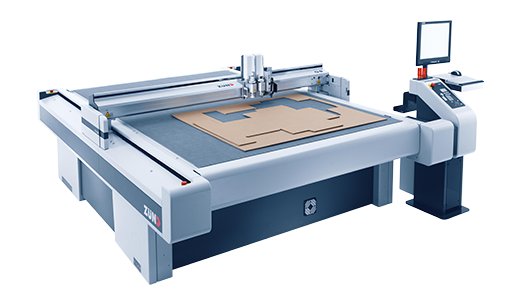

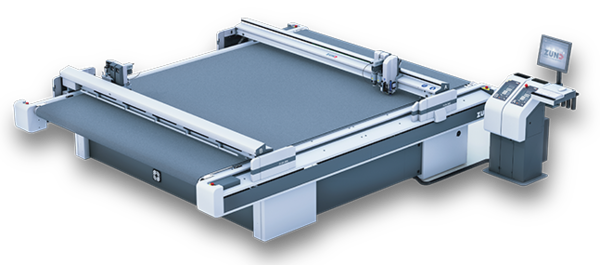

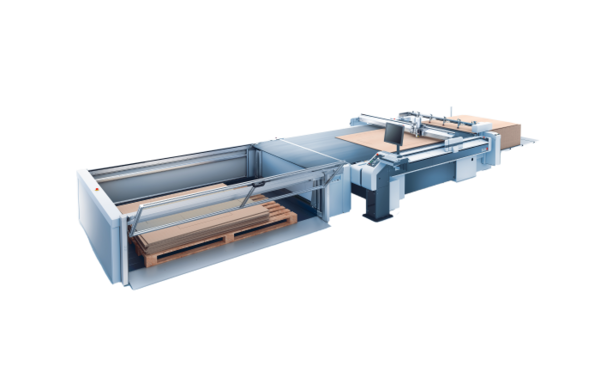

With a Zünd Digital Cutter, packaging made of solid board, corrugated board, cardboard and transparent materials such as PP, PET and PVC can be produced individually and in high quality.

The modular system, which sets the Swiss company apart from its competitors, enables a wide range of functions, such as accurate cutting, creasing, stamping, drawing, trimming or perforating. Thanks to the modular system, the flexible adaptation of all Zünd cutters is just as naturally as the subsequent upgrading of existing machines.

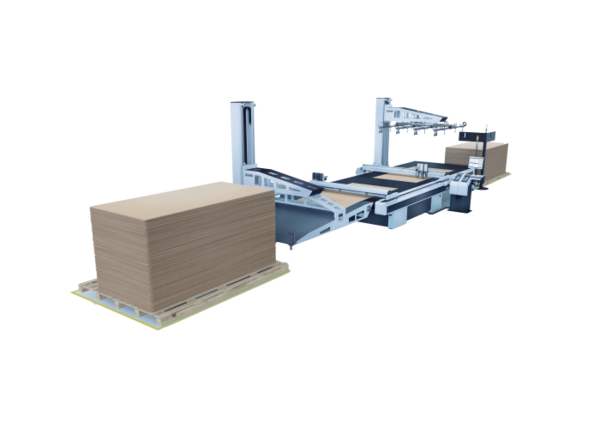

A perfect workflow with Zünd digital cutting systems and VPack ®

The integration of Zünd high-performance plotters to the 3D CAD/CAM packaging software VPack ® aims to optimise the workflow in the packaging industry. The interface makes it possible to seamlessly organise the entire packaging production process - from the design and construction idea to prototype development and the actual production.

With VPack ® you can configure any packaging elements made of e.g. folding carton, corrugated board, sandwich material, PP, PVC, lightweight foam sheets or foam and transfer the construction data directly to the Zünd plotter without the need for manual work steps or conversions.

The connection of the CAD/CAM software to Zünd cutters leads overall to an improved and more efficient digital production of the packaging. It helps to enhance quality, reduce production time and decrease costs. At a time when the packaging industry is increasingly dependent on faster time-to-market and customised solutions, this is of particular importance.